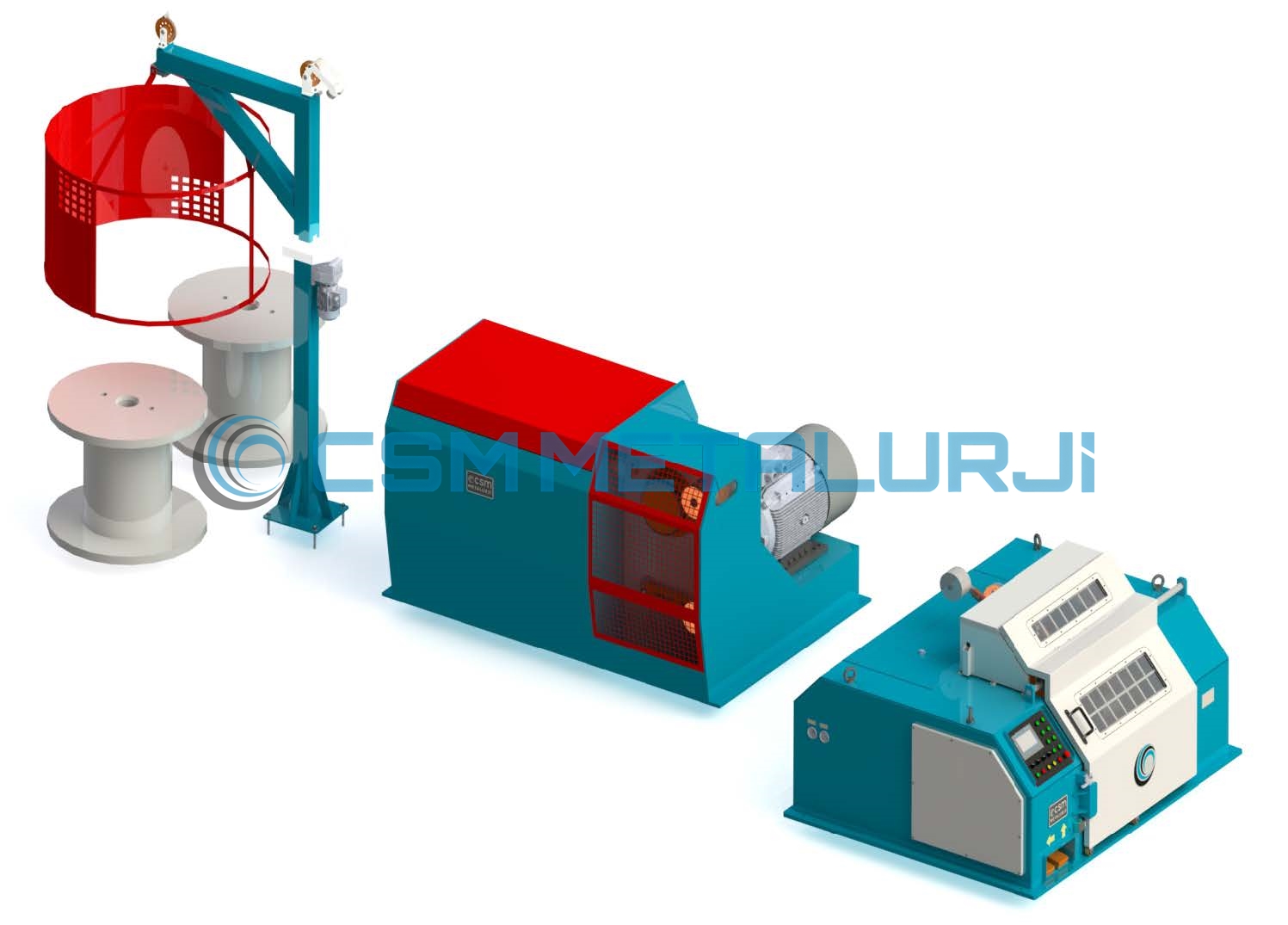

The machine bodies are produced in a modular and robust structure with the aim of being easy to move and install. Machine protection covers are designed taking into account operational efficiency and safety precautions.

The first block of the wire drawing machines that feed the wire rod are produced as OTO TYPE which accumulates in the vertical position depending on demand. The last block can be produced as a vertical type and STRIPPER block.

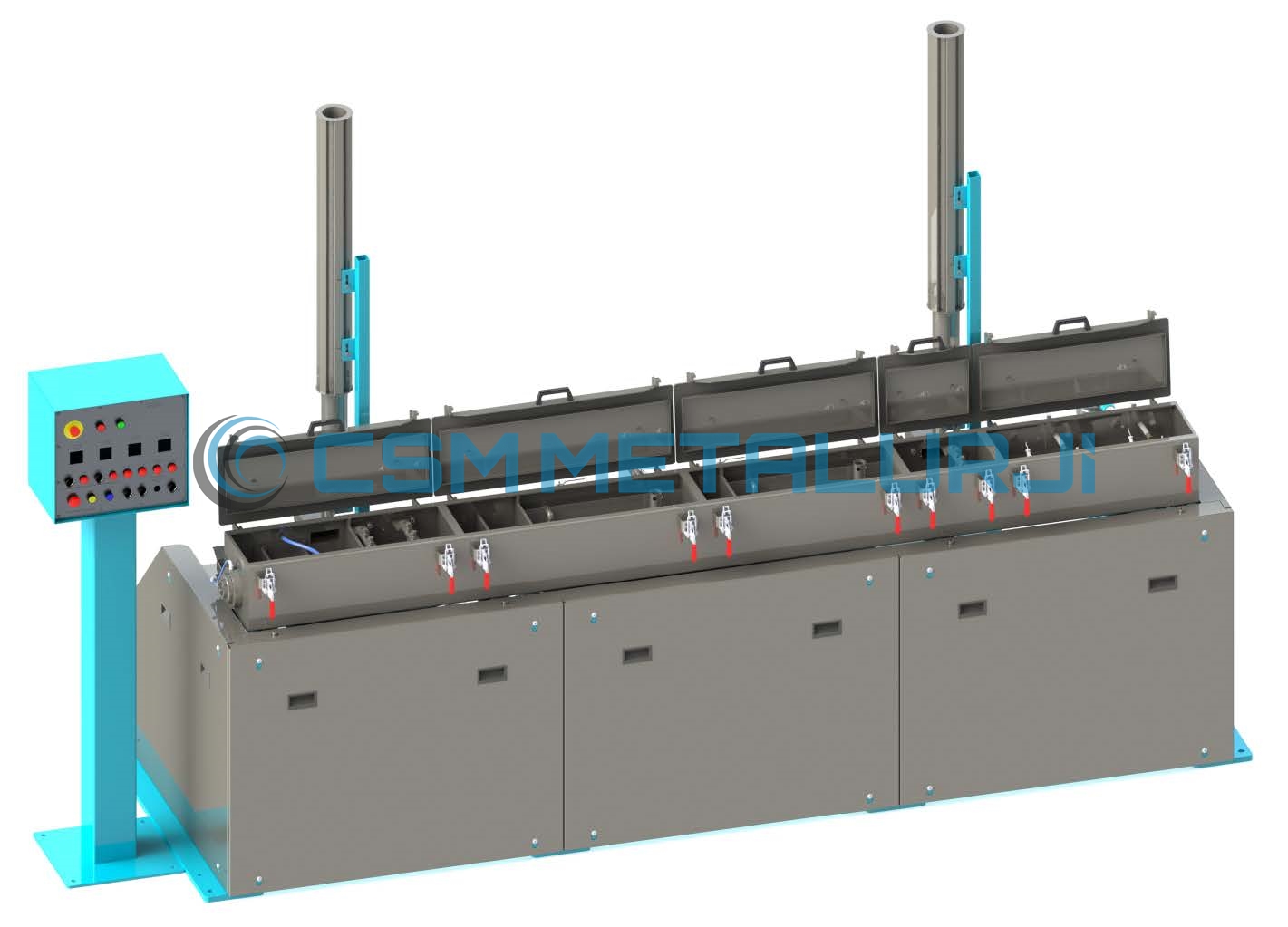

Depending on request, die box or micro-cassette type machine production is carried out in different steel qualities and taking into consideration wire input-output diameters. Fixed or rotating type die boxes are manufactured with direct water cooled. Last block die box of drawing machines is also designed to be used liquid soap especially for bright wire production.

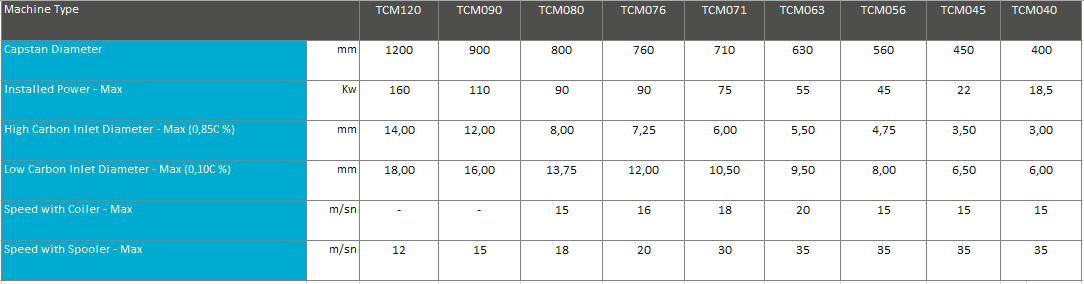

Up to 16,00 mm of wire rod can be used and 0,80 mm wire can be produced and 35 m / sec speeds can be achieved.

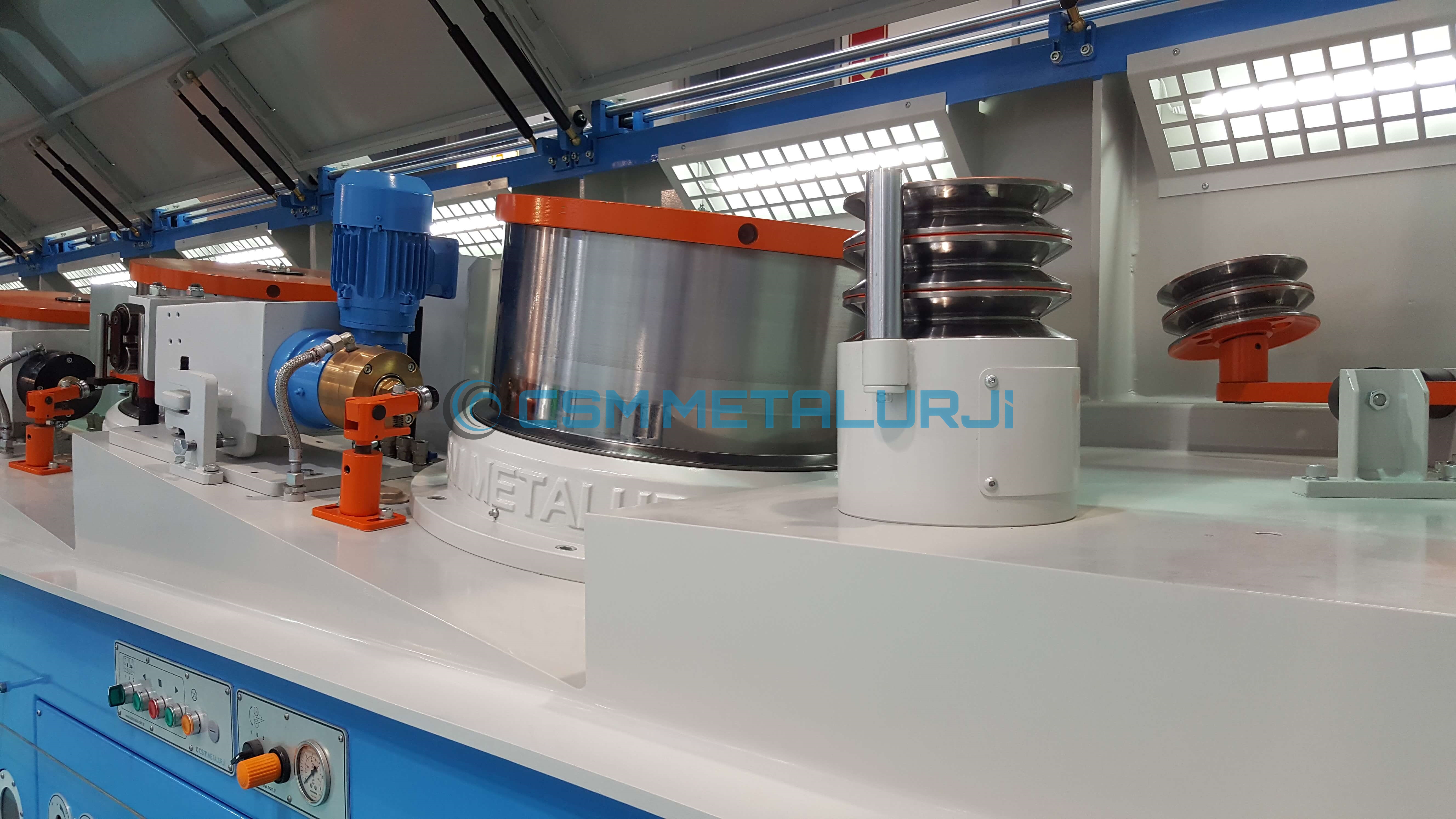

Drawing capstans are manufactured from 4140 grade steel casting material. After induction hardening heat treatment is applied, tungsten carbide coating is applied and polished Thus, a long service life is ensured.

Drawing capstans can be manufactured both air and water cooled and only water cooled by using corrosion resistant materials

Pneumatic braking systems are used in drawing blocks. The electrical motors are specially prepared for the encoder system. Block gearboxes can have an external or internal oil pump.

In the automation system of the machines, the latest version SIEMENS PLC, software and PROFINET communication protocol are used. Speed synchronization is provided by dancer arms. Cooling water temperatures, capstan drive group temperatures are controlled by the automation system.

In CSM METALURJI, wire drawing machines are produced with both die and micro cassette rolling, which can be replaced with each other. In micro cassettes, the world's best quality tungsten carbide rollers are used. With a series of micro cassettes, up to 5600 tons of wire with a diameter of 1.80 mm can be precisely produced. The water cooling system and the automatic lubrication system infrastructure for the microcassettes can be available in the machines.